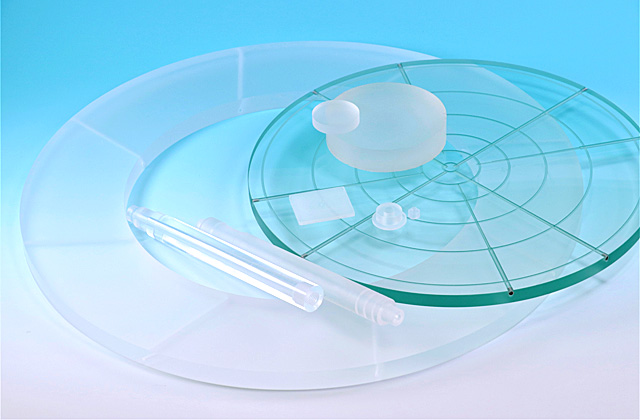

The combination of thermal, chemical and UV stability together with high DUV transparency make them an excellent choice for projection masks for photolythography.

The dielectric properties and very high electrical receptivity of these materials over a wide range of temperatures together with their low thermal conductivity allow their use as an electrical and thermal insulating material in wide range of environments. These materials are inert to most substances, including virtually all acids, allowing their use in rather severe environments. All this together with excellent transmission in compare with most other glasses make them useful materials for production of superior quality optical windows, lenses, prisms, beam-splitters, beam-combiners, cold/hot mirrors, et cetera, and so on.

These materials can routinely withstand temperatures of over 950☌ and due to their very low coefficient of thermal expansion can be rapidly heated and cooled with virtually no risk of breakage due to thermal shock. The very high purity (over 99.9%) ensures minimum contamination in process applications. UV-IR grade of synthetic FS (KS-4V) produced by complex process which involves chemical gasification of silicon, oxidation of this gas to silicon dioxide (SiO 2), and thermal fusion of the resulting ash in vacuum.īoth Synthetic Fused Silica grades are ultra pure, single component glasses with a unique combination of thermal, optical and mechanical properties, which make them the preferred materials for use in a variety of processes and applications where other materials are not suitable.UV grade of synthetic FS (KU-1) produced by continuous high temperature hydrolysis of silicon tetrachloride - SiCl4 in hydrogen-oxygen flame.Synthetic Fused Silica is made from a silicon-rich chemical precursor and there are two main grades of the material which are widely utilized for optical manufacturing: This opacity is caused by very small air bubbles trapped within the material. Fused Quartz is normally transparent.įused Silica is produced using high purity silica sand as the feedstock and is normally melted using an electric furnace, resulting in a material that is translucent or opaque.

They are manufactured using several different processes.įused Quartz is made by melting of high purity naturally occurring quartz crystals at around 2000☌ using either an electrically heated furnace (electrically fused) or a gas/oxygen-fuelled furnace (flame fused).

#Silica glass download#

Download Quartz Glass Datasheet (PDF, 119 KB)įused Quartz and Fused Silica are types of Quartz Glass containing primarily silica in amorphous form.

0 kommentar(er)

0 kommentar(er)